2025 Top Cargo Storage Containers for Effective Space Management

In today's fast-paced logistics and supply chain industry, efficient space management is crucial for maximizing productivity and minimizing costs. As businesses continue to expand, the demand for innovative cargo storage solutions has grown exponentially. According to logistics expert Dr. Sarah Whitmore, "The right cargo storage containers can transform the way we approach inventory management and space utilization." This statement underscores the importance of selecting the appropriate containers to streamline operations and enhance workflow.

As we delve into the top cargo storage containers of 2025, we will explore designs and features that cater to diverse industry needs. These containers not only provide ample space for goods but are also engineered to optimize accessibility and organization. From high-capacity units to modular designs that allow for flexible configurations, the advancements in cargo storage technology are paving the way for more effective space management strategies.

Ultimately, the right choice of cargo storage containers can significantly impact a company's bottom line, ensuring that businesses adapt to the changing landscape of logistics with ease and efficiency. As we move forward, understanding the best options available will empower businesses to make informed decisions about their storage solutions.

Overview of Cargo Storage Containers for Space Management

Cargo storage containers have become indispensable tools for efficient space management in various industries. These containers offer a versatile solution for organizing goods, materials, and equipment, maximizing available space while minimizing clutter. With advancements in design and materials, modern cargo containers are not only durable and secure but also customizable to fit specific storage needs. Industries such as logistics, warehousing, and even construction benefit from these innovative storage solutions, which allow for better inventory control and accessibility.

In addition to traditional shipping containers, a variety of specialized cargo storage solutions have emerged in recent years. Options such as collapsible containers, modular storage systems, and temperature-controlled units cater to different requirements, from perishable goods to sensitive electronics. Implementing a strategic approach to cargo container usage can significantly enhance operational efficiency and streamline space management. By evaluating the particular needs of a business and selecting the right container types, companies can optimize their storage processes and reduce overhead costs.

2025 Top Cargo Storage Containers for Effective Space Management

| Container Type | Dimensions (ft) | Weight Capacity (lbs) | Material | Key Features |

|---|---|---|---|---|

| Standard Shipping Container | 20 x 8 x 8.5 | 5,000 | Steel | Weather-resistant, stackable |

| Refrigerated Container | 40 x 8 x 9.5 | 10,000 | Steel/Insulated | Temperature control, secure |

| High Cube Container | 40 x 8 x 9.5 | 5,500 | Steel | Extra height, optimal for bulky goods |

| Flat Rack Container | 20 x 8 x 5.5 | 40,000 | Steel | Suitable for heavy machinery and cargo |

| Open Top Container | 20 x 8 x 8.5 | 5,000 | Steel | Easily loaded from the top |

Key Features to Look for in Effective Cargo Storage Solutions

When selecting cargo storage containers for effective space management, several key features can make a significant difference. First and foremost, the durability of the container material is essential. Opting for containers made from high-quality steel or reinforced plastic ensures that they can withstand harsh weather conditions and heavy loads. Additionally, containers with anti-corrosive coatings can extend their lifespan, making them a more dependable choice for long-term storage.

Another critical feature to consider is the container's versatility. Containers with adjustable shelving and modular designs allow for greater flexibility in organizing cargo, maximizing the use of available space. Furthermore, ease of access is vital; containers that come with wide doors and are stackable enable efficient loading and unloading processes, minimizing time and labor costs. Lastly, incorporating security features such as lockable doors and tamper-proof designs can provide peace of mind, ensuring that your cargo is safe and protected from unauthorized access. These features collectively enhance the effectiveness of cargo storage solutions, leading to optimized space management.

2025 Top Cargo Storage Containers for Effective Space Management

Top 2025 Cargo Storage Container Models and Their Applications

As we approach 2025, the cargo storage container industry continues to innovate, offering a variety of models tailored for diverse applications. One of the standout options is the High Cube Container, which provides an extra foot of vertical space, making it ideal for businesses that require additional storage capacity without increasing footprint. This model is particularly employed in sectors such as retail, where maximizing storage efficiency is crucial for managing inventory effectively.

Another noteworthy model is the Open Top Container, designed for transporting oversized cargo that cannot fit into standard containers. This versatility is especially valuable in industries like construction and machinery, where large equipment and materials are common. The tarpaulin roof allows for easy loading from above, eliminating the difficulties associated with transporting bulky items.

As companies look towards the future, selecting the right container model will be essential for optimizing storage capabilities and catering to specific operational needs.

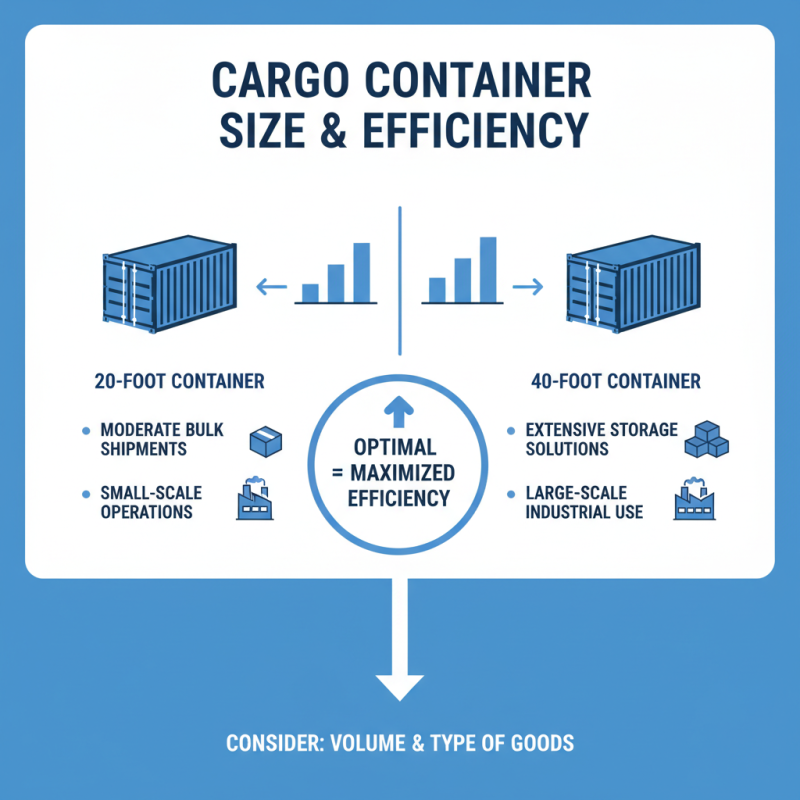

Comparative Analysis of Container Sizes and Designs for Efficiency

In the realm of cargo storage, efficiency is paramount, and the choice of container size and design can significantly impact space management. A comparative analysis reveals that different container sizes cater to varied storage needs, from small-scale operations to large-scale industrial applications. For instance, standard 20-foot containers are ideal for moderate bulk shipments, while 40-foot units provide greater capacity for businesses requiring more extensive storage solutions. Understanding the volume and type of goods to be stored can guide businesses in selecting the optimal container size that maximizes their inventory efficiency.

Moreover, the design of cargo containers plays a crucial role in their functionality. Features such as double doors, refrigeration units, and modular designs enhance accessibility and adaptability in diverse environments. Innovative designs, including collapsible containers, facilitate better space utilization during off-peak times, thereby reducing overhead costs. By carefully assessing the interplay between size and design, companies can not only streamline their logistics but also make informed decisions that bolster their operational efficiency and responsiveness in a competitive market.

Best Practices for Organizing and Maximizing Space with Containers

Organizing and maximizing space effectively is crucial for businesses looking to streamline their operations. According to a recent report by the Container Storage Association, efficient space management can boost productivity by up to 20%. Utilizing cargo storage containers strategically allows companies to reduce clutter and make optimal use of their available area. For instance, vertical storage solutions can significantly enhance space utilization while keeping items easily accessible.

Tip: Implement a color-coding system for your containers. By categorizing items based on their usage frequency or type, you’ll simplify the retrieval process and maintain an organized workspace. This not only saves time but also reduces the risk of inventory discrepancies.

In addition to organization, regular audits of container contents can help maintain effectiveness. A study from the National Facility Management Association found that businesses that regularly assess their storage systems can uncover hidden inefficiencies, leading to potential cost savings of 15% or more. By integrating mobile shelving with cargo containers, companies can adapt to changing needs and maximize their storage capabilities.

Tip: Schedule seasonal inventory checks to reassess what’s being stored in your containers. This practice can help identify any outdated or unnecessary items that can be discarded or donated, keeping your storage solutions relevant and efficient.

Related Posts

-

Revolutionizing Food Storage with Shipping Container Freezers for Sustainable Business Solutions

-

Transforming Your Home Office with a 20ft Shipping Container Solution

-

Innovative Shipping Container Conversions Driving Sustainable Living Trends in Urban Areas

-

Unlocking Sustainability: Innovative Uses of Cargo Containers in Green Architecture

-

Maximize Your Space with a 10ft Shipping Container for Tiny Living Solutions

-

2025 Top 5 One Trip Shipping Containers: Best Choices for Your Needs

Get a quote

Get a quote

Read More

Accept AllReject AllCustomise

Privacy Overview

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie records the user consent for the cookies in the "Advertisement" category. |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| CookieLawInfoConsent | 1 year | CookieYes sets this cookie to record the default button state of the corresponding category and the status of CCPA. It works only in coordination with the primary cookie. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _cs_c | 1 year 1 month | The cookie is used by Content Square to save the user consent to be tracked. |

| Cookie | Duration | Description |

|---|---|---|

| _cs_id | 1 year 17 days 20 hours 13 minutes | This cookie is used to store the ContentSquare's user identifier ID. This is a persistent cookie and expires after 13 months. |

| _cs_s | 1 hour | This cookie is used to store the number of page's viewed by a visitor within the session for ContentSquare's solution. |

| _ga | 1 year 1 month 4 days | Google Analytics sets this cookie to calculate visitor, session and campaign data and track site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognise unique visitors. |

| _ga_* | 1 year 1 month 4 days | Google Analytics sets this cookie to store and count page views. |

| _gcl_au | 3 months | Google Tag Manager sets the cookie to experiment advertisement efficiency of websites using their services. |

| Cookie | Duration | Description |

|---|---|---|

| test_cookie | 15 minutes | doubleclick.net sets this cookie to determine if the user's browser supports cookies. |

| Cookie | Duration | Description |

|---|---|---|

| _cs_root-domain | session | Description is currently not available. |

| _cs_same_site | session | Description is currently not available. |